I. Introduction

- Background: In the construction and engineering industries, used excavators are widely favored for their cost-effectiveness and efficiency. However, purchasing used equipment involves multiple factors and requires careful consideration.

- Purpose and Significance: This guide aims to help buyers identify and understand key registration information such as origin, year, model, and manufacturer, enabling them to make informed purchasing decisions and ensure the performance and reliability of the equipment.

II. Importance of Purchasing Used Excavators

- Cost-Effectiveness: Compared to new models, used excavators typically come at a lower purchase cost, making them suitable for businesses or individuals with limited budgets. A well-informed choice can save money while meeting project needs.

- Performance Assessment: Understanding the excavator’s usage history, maintenance records, and operational status can help buyers evaluate its performance and reliability, avoiding the purchase of frequently malfunctioning equipment.

III. Key Registration Information Checkpoints

1. Origin

- Importance of Origin: Different regions have varying manufacturing standards and quality control levels. Knowing the origin helps buyers assess the manufacturing process and quality of the equipment.

- Brand Impact: Well-known brands generally have a good reputation in the market, ensuring better quality and after-sales service. Choosing a reputable brand for a used excavator can reduce purchasing risks.

- Imported vs. Domestic: Comparing the pros and cons of imported and domestic excavators. Imported models may feature more advanced technology, but maintenance and parts supply can be challenging; whereas domestic models often offer better after-sales service and easier access to parts.

2. Year

- Impact of Production Year: The production year directly affects the technology level, market value, and remaining lifespan of the equipment. Typically, newer equipment adheres to higher technical standards and shows less wear.

- Maintenance and Repair Records: The production year is closely related to the equipment’s maintenance history. Newer machines, when well-maintained, tend to have longer lifespans. Checking maintenance records helps buyers gauge the actual condition of the equipment.

3. Model

- Identification of Model: Different models of excavators may exhibit significant differences in performance specifications, applicable scenarios, and technical parameters. Knowing the specific characteristics of a model helps buyers select equipment that meets their needs.

- Model and Market Demand: Some models may have higher demand and popularity in the market, affecting their used value. Selecting a model with strong market demand makes future resale easier.

4. Manufacturer

- Manufacturer Reputation: Well-known manufacturers typically provide better quality assurance, along with comprehensive after-sales support and technical assistance. Understanding the manufacturer’s market reputation helps mitigate purchasing risks.

- After-Sales Service and Support: It’s important to know the manufacturer’s after-sales service policies to ensure necessary technical support and parts supply post-purchase. This directly impacts the user experience with the equipment.

IV. Additional Checkpoints

1. Equipment Usage Condition

- Usage Hours: Reviewing the equipment’s usage hours is a key indicator of wear. Generally, machines with fewer hours show less wear and tear.

- Working Environment: Understanding the working environment can reveal if the equipment has operated under harsh conditions. Equipment that has worked in extreme conditions (high temperature, humidity, or dusty environments) may suffer from performance and longevity issues.

2. Maintenance Records

- Maintenance History: Checking the equipment’s maintenance logs ensures it has received regular upkeep. A good maintenance record often indicates that the equipment is in sound working condition.

- Parts Replacement: Understanding whether any major components (like the engine or hydraulic pump) have been replaced is crucial. Replaced parts often signify necessary maintenance has been performed, potentially increasing reliability.

3. On-Site Inspection

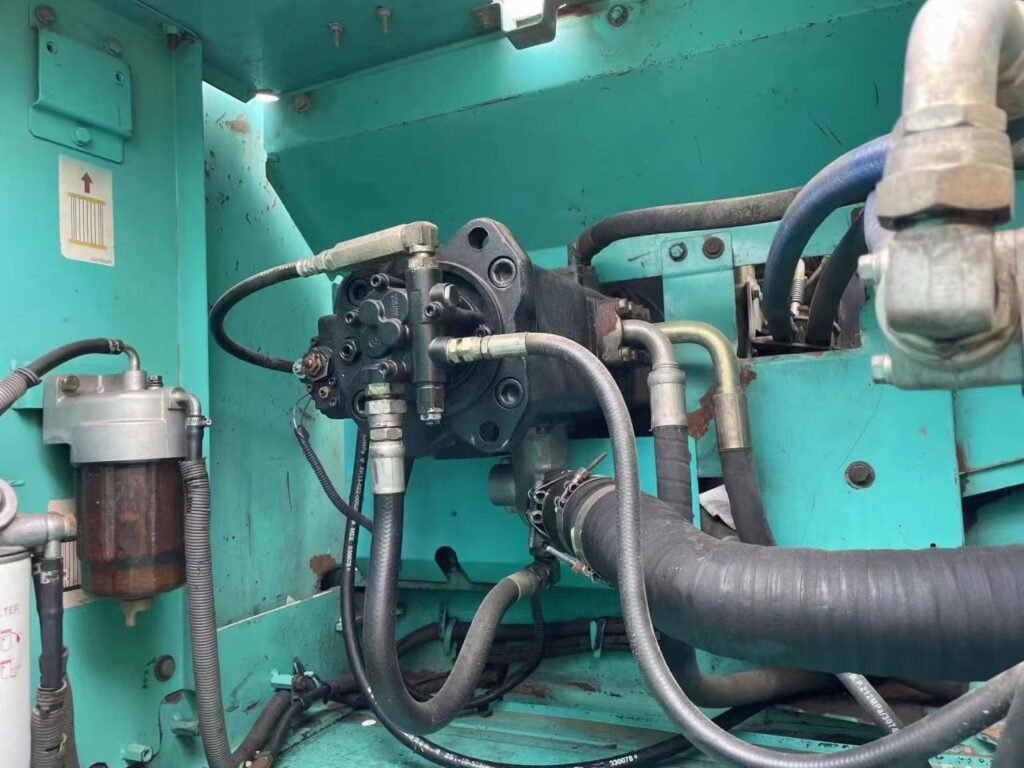

- Visual Inspection: Conduct a thorough visual inspection of the equipment, including the body, hydraulic system, and tracks. Any visible damage or rust may indicate underlying issues.

- Functionality Test: Perform basic functionality tests to ensure all equipment functions are operating correctly. This includes checking the movement of the bucket, the responsiveness of the hydraulic system, and the starting and running conditions of the engine.

V. Summary and Recommendations

- Key Takeaways: Reiterate the importance of key registration information (such as origin, year, model, and manufacturer) in the process of purchasing a used excavator, along with the significance of additional checkpoints in ensuring equipment reliability.

- Purchasing Advice: Advise buyers to conduct thorough research before making a purchase and to consult professionals to ensure the equipment meets their needs. Given the complexity of the used market, it is recommended to remain cautious during transactions and ensure transparency and fairness in contract terms.