I. Introduction

- Background: Excavators are indispensable heavy machinery in construction projects, and their fuel consumption directly impacts operational costs and environmental benefits. With increasingly stringent environmental regulations, companies face pressure to reduce energy consumption and emissions. Therefore, implementing energy-saving strategies not only lowers operational costs but also enhances the company’s image regarding social responsibility.

- Purpose and Significance: This guide aims to share efficient operation and maintenance techniques to help users effectively reduce excavator energy consumption and improve economic benefits, achieving sustainable development. Through this guide, users will gain practical energy-saving strategies to optimize equipment usage and management.

II. Factors Affecting Excavator Energy Consumption

1. Operating Habits

- Operator Skills: The experience and skill level of operators directly influence excavator energy consumption. Skilled operators can control the equipment more efficiently, reducing unnecessary energy use.

- Operating Methods: Different operational techniques and habits significantly affect fuel consumption. For example, smooth handling and reasonable work rhythm can effectively reduce fuel expenditure.

2. Equipment Condition

- Equipment Maintenance: Regular maintenance and servicing of equipment ensure efficient operation, prolong equipment lifespan, and reduce fuel consumption. Neglected equipment may lead to increased energy use.

- Component Wear: The degree of wear on equipment components directly impacts energy consumption. Timely replacement or repair of worn parts keeps the equipment performing at its best, thereby lowering fuel use.

3. Working Environment

- Working Conditions: Various terrains, soil types, and climatic conditions influence excavator energy consumption. For example, operating in hard soil requires more power, leading to higher fuel consumption.

- Type of Operation: Light-duty and heavy-duty operations have different impacts on energy consumption. Understanding the type of work helps in selecting appropriate equipment and methods.

III. Efficient Operating Techniques

1. Operator Training

- Skill Enhancement: Provide regular training for operators to improve their skills and energy-saving awareness. Training should include efficient operating methods and energy-saving techniques.

- Energy Awareness: Cultivate operators’ energy-saving consciousness through training, encouraging them to adopt energy-efficient operational methods, such as using economy modes and properly planning tasks.

2. Rational Scheduling

- Work Planning: Develop reasonable work schedules to avoid unnecessary idling and repetitive tasks, thereby reducing fuel consumption.

- Equipment Configuration: Appropriately configure excavators based on actual work requirements to prevent excessive energy use.

3. Optimization of Operating Techniques

- Smooth Operation: Operators should avoid sudden acceleration and deceleration, maintaining smooth operation to effectively reduce energy consumption.

- Appropriate Use of Attachments: Select suitable attachments based on work needs to enhance efficiency and lower energy use.

IV. Effective Maintenance Techniques

1. Regular Maintenance

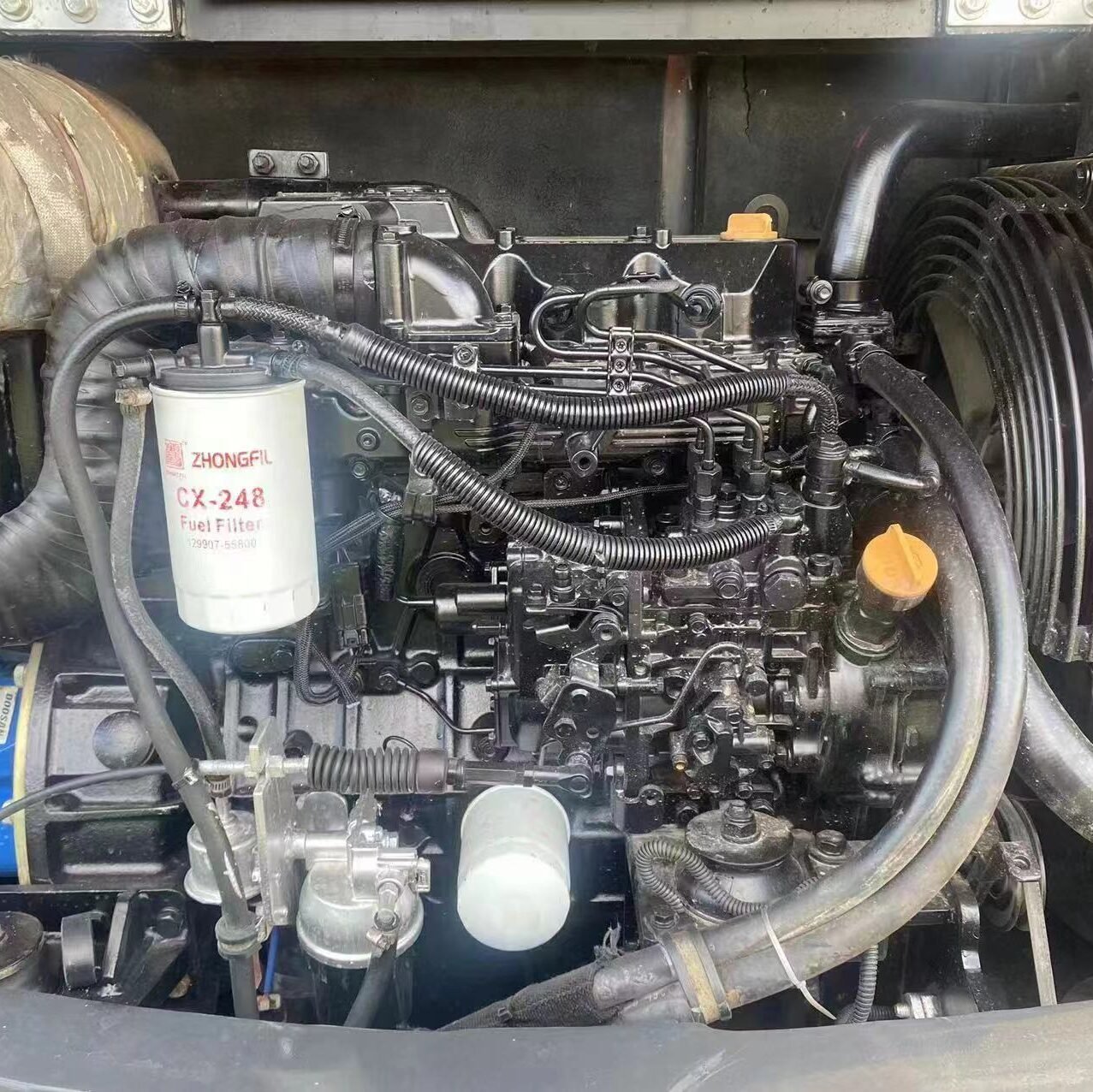

- Maintenance Plans: Establish detailed regular maintenance schedules for equipment, including daily checks, weekly tasks, and monthly maintenance activities to ensure all critical components are functioning properly. These plans should cover hydraulic systems, engines, and transmission systems to prevent potential failures.

- Fluid Checks: Regularly inspect hydraulic fluids, engine oils, and coolant levels and quality to ensure adequate lubrication. Contaminated or aged fluids can lead to increased energy consumption, making timely fluid changes essential. Additionally, regularly clean oil filters and hydraulic filters to maintain system cleanliness.

2. Component Replacement

- Timely Replacement: Implement a mechanism for regular inspections and timely replacements of components, especially heavily worn parts such as bucket teeth, tracks, and hydraulic cylinders. Worn components not only affect work efficiency but also lead to increased energy consumption.

- Use Quality Parts: Choose high-quality original parts or certified alternatives to avoid using inferior components. Quality parts can enhance equipment operating efficiency, reduce failure rates, and further decrease energy consumption.

3. Fault Prevention

- Fault Detection: Utilize modern technologies such as sensors and monitoring systems to track equipment performance in real-time. Data analysis can help identify potential issues early on, allowing for preemptive measures. For instance, if oil temperatures rise or pressure anomalies occur, immediate inspection and action are necessary.

- Data Monitoring: Establish a data monitoring system to collect and analyze operational data, including fuel consumption, operating hours, and load conditions. By analyzing this data, users can optimize equipment usage strategies and adjust maintenance plans to ensure that equipment operates at peak efficiency.

V. Case Studies

1. Successful Cases

- Energy Saving Results: Share a successful case from a construction project that implemented energy-saving measures. In this project, through regular operator training and optimized work scheduling, fuel consumption for excavators was reduced by 20%. The entire team improved work efficiency by employing smooth operating techniques and effectively configuring equipment, leading to shortened project timelines.

- Best Practices: Summarize best practices from this project, such as how to create detailed work plans at the project’s outset and how continuous operator training can enhance the team’s energy-saving awareness. These experiences not only improved the project’s economic benefits but also provided valuable references for future engineering projects.

2. Failure Cases

- Lessons Learned: Discuss a mining project that experienced high energy consumption due to neglecting equipment maintenance. In this project, failure to perform regular maintenance led to hydraulic system failures, resulting in a 30% increase in fuel consumption. Analysis revealed that operators lacked energy-saving awareness, failing to effectively control work rhythms.

- Improvement Recommendations: Summarize lessons from this case, emphasizing the importance of regular maintenance and operator training. Recommend that other projects conduct thorough pre-use inspections and ensure operators receive necessary training to avoid similar issues. Additionally, establish effective communication mechanisms to ensure all team members understand the importance of energy saving and participate collectively.

VI. Summary and Outlook

- Key Takeaways: Summarize the importance of energy saving and consumption reduction for excavators, emphasizing the dual role of efficient operation and maintenance.

- Future Trends: Explore future trends in excavator technology and discuss the potential impacts of new technologies (such as electric excavators and intelligent systems) on energy saving and consumption reduction, promoting sustainable development in the industry.