I. Introduction

- Background: With the rapid development of the construction and engineering industries, used excavators are increasingly favored by companies due to their relatively low prices and good performance. Proper maintenance of these machines can significantly extend their lifespan and improve work efficiency.

- Purpose and Significance: This guide aims to provide users with systematic maintenance methods for used excavators. Through regular upkeep and timely repairs, users can reduce equipment failure rates and maintenance costs, thereby achieving greater returns on investment.

II. Characteristics of Used Excavators

1. Pre-Purchase Inspection

- Key Inspection Items: When purchasing a used excavator, users should focus on several aspects:

- Engine: Check the engine’s starting performance, operational sounds, and fuel consumption.

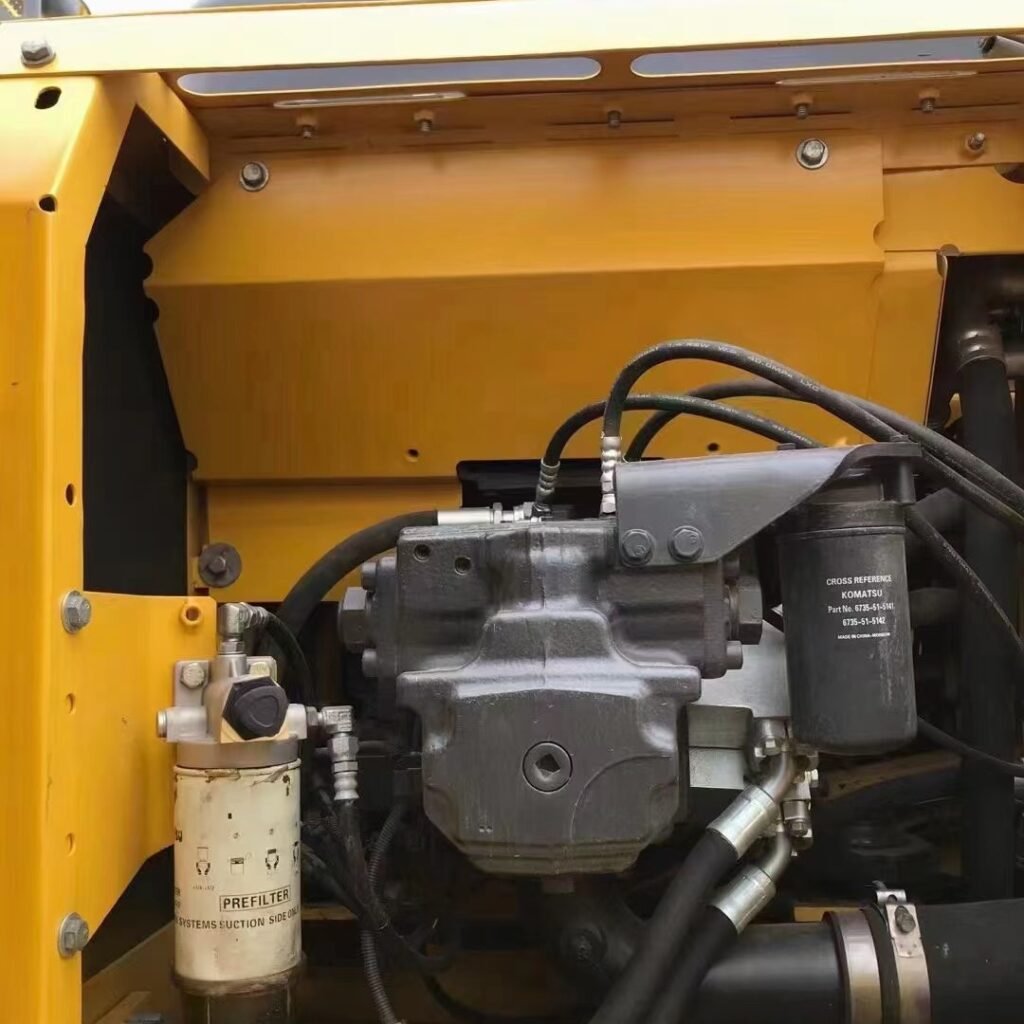

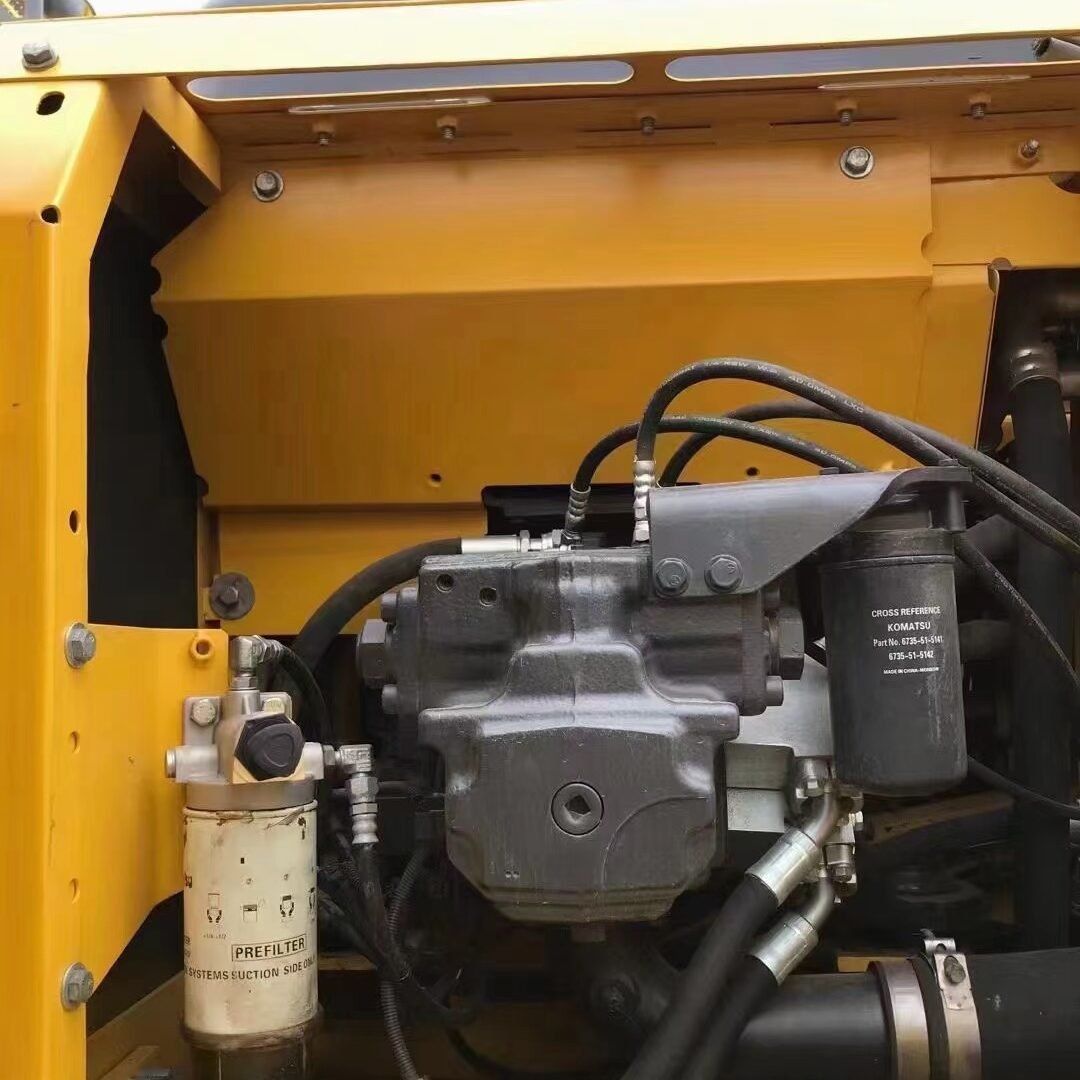

- Hydraulic System: Ensure that the hydraulic system maintains proper pressure and has no leaks.

- Chassis and Tracks: Observe the wear level of the chassis and the aging condition of the tracks to ensure stability.

- Historical Records: Understanding the equipment’s history is crucial, including:

- Maintenance Records: Review the maintenance history to assess how well the equipment has been cared for.

- Usage Conditions: Confirm the usage frequency and working environment to evaluate its suitability for your needs.

2. Common Issues

- Aging and Wear: Analyze common aging and wear issues in used excavators, such as:

- Hydraulic Seals Aging: This can lead to hydraulic leaks, negatively affecting work efficiency.

- Engine Component Wear: Such as cylinder and piston ring wear, which can lead to decreased power output.

- Technological Updates: Rapid technological advancements mean that newer models significantly outperform older ones, prompting users to consider:

- Comparison with New Equipment: Understand where older equipment lags technologically and assess whether an upgrade is necessary.

III. Daily Maintenance

1. Regular Inspections

- Fluid Checks: Regularly check the following fluids:

- Engine Oil: Ensure oil levels and quality to avoid excessive engine wear.

- Hydraulic Oil: Check the oil level and color to ensure proper functioning.

- Coolant: Monitor coolant levels to prevent overheating.

- Filter Replacement: Describe the timing and methods for replacing air and oil filters:

- Air Filter: Replace every 500 hours to maintain engine air intake.

- Oil Filter: Change every 1000 hours to keep the oil system clean.

2. Cleaning and Maintenance

- External Cleaning: Emphasize the importance of regularly cleaning the excavator’s exterior:

- Prevent Dirt Accumulation: Regularly wash the equipment to prevent dirt and debris from affecting performance and to ensure proper cooling.

- Internal Inspections: Regularly check the hydraulic and electrical systems:

- Hydraulic System: Inspect hydraulic lines for leaks to maintain proper fluid pressure.

- Electrical System: Ensure electrical connections are secure for stable power supply.

IV. Seasonal Maintenance

1. Summer Maintenance

- Cooling System Checks: In high temperatures, inspect the radiator and coolant:

- Clean the Radiator: Ensure the radiator has good airflow to prevent overheating.

- Dust Protection Measures: Implement dust protection measures to safeguard equipment in dry conditions:

- Install Dust Covers: Use dust covers during dry seasons to prevent dirt from entering the machine.

2. Winter Maintenance

- Antifreeze Checks: Inspect the concentration of antifreeze to ensure normal operation in low temperatures:

- Use Appropriate Antifreeze: Confirm that antifreeze concentration meets equipment specifications to prevent freezing.

- Battery Maintenance: Regularly check battery status to ensure it starts normally in cold weather:

- Clean Battery Terminals: Periodically clean battery terminals to prevent oxidation.

V. Troubleshooting and Repairs

1. Common Faults

- Engine Issues: Identify common engine problems, such as:

- Starting Difficulties: May be caused by low battery charge or fuel supply issues.

- Unusual Noises: Can indicate internal component wear or insufficient lubrication.

- Hydraulic System Problems: Analyze common hydraulic issues and troubleshooting steps:

- Insufficient Pressure: Check hydraulic oil levels and inspect for blockages in the lines.

- Leakage: Examine hydraulic seals and fittings for any signs of leaks.

2. Repair Techniques

- Professional Repairs vs. DIY Maintenance: Discuss when to seek professional repair services:

- Complex Issues: For internal engine failures or major hydraulic repairs, professional help is recommended.

- Simple Maintenance: Tasks like replacing filters and fluids can often be performed by the owner.

- Spare Parts Management: Introduce how to manage commonly used spare parts to improve repair efficiency:

- Create a Parts List: Keep a record of commonly used parts and their quantities to ensure quick access during repairs.

VI. Conclusion and Recommendations

- Key Findings: Summarize the importance of effective maintenance for used excavators, highlighting how regular upkeep can extend equipment lifespan and improve work efficiency.

- Practical Suggestions: Offer practical advice for users, including:

- Establish a Maintenance Schedule: Develop a detailed maintenance plan and conduct regular inspections and upkeep.

- Keep a Maintenance Log: Record each maintenance activity, allowing for better tracking of equipment status and facilitating future management.